Application and Future Trends of Small CNC Milling Machines in Developing Countries: Focus on South America

Introduction

Small CNC (Computer Numerical Control) milling machines have emerged as transformative tools in manufacturing, particularly in developing economies such as those in South America. Their affordability, precision, and adaptability make them ideal for addressing the region’s evolving industrial demands. This report explores their current applications, challenges, and future growth potential in these markets.

Current Applications in South America

1. SMEs and Artisanal Workshops

Small CNC mills are widely adopted by small and medium-sized enterprises (SMEs) and artisanal workshops in countries like Brazil, Colombia, and Argentina. These machines enable cost-effective production of custom parts, prototypes, and tooling, supporting local industries such as automotive repair, furniture design, and agricultural equipment manufacturing.

2. Education and Skill Development

Technical schools and vocational training centers increasingly use small CNC mills to train students in modern manufacturing techniques. For example, initiatives in Peru and Ecuador integrate these machines into curricula to bridge the skills gap and prepare workers for advanced manufacturing roles.

3.Localized Production

Rising import costs and supply chain disruptions (e.g., during the COVID-19 pandemic) have driven demand for localized production. Small CNC mills empower businesses to manufacture components domestically, reducing reliance on foreign suppliers. Industries like medical device manufacturing in Chile and aerospace subcontracting in Brazil exemplify this trend.

4.Creative Industries

Artists and designers leverage small CNC mills for intricate woodworking, jewelry making, and architectural modeling. In regions with strong cultural heritage, such as Bolivia and Paraguay, these machines blend traditional craftsmanship with digital precision.

Challenges

High Initial Investment**: Despite lower costs compared to industrial CNC systems, financing remains a barrier for micro-enterprises.

Technical Training**: Limited access to skilled operators and maintenance expertise hinders adoption.

Infrastructure Issues**: Unstable power supply and poor internet connectivity in rural areas affect machine performance and IoT integration.

Future Trends

1. Cost Reduction and Accessibility

Advances in open-source CNC software (e.g., GRBL) and cheaper components will drive affordability. Local assembly initiatives, such as Brazil’s "Made in Brazil" CNC kits, aim to reduce import dependency.

2. Digitalization and Industry 4.0

Integration with cloud-based platforms and AI-driven predictive maintenance will enhance efficiency. Governments in Argentina and Colombia are incentivizing SMEs to adopt smart manufacturing technologies.

3. Sustainable Manufacturing

Solar-powered CNC mills and recycled material compatibility align with global sustainability goals. Projects in Ecuador’s renewable energy sector highlight this potential.

4. Government and Private Sector Partnerships

Programs like Colombia’s "Industria 4.0 Roadmap" and Brazil’s "Innovate Manufacturing Fund" promote CNC technology adoption through subsidies and training hubs.

5. Expansion into Niche Markets

Demand for small CNC mills will grow in sectors such as renewable energy (e.g., turbine parts), medical devices, and electric vehicle components.

Conclusion

Small CNC milling machines are reshaping South America’s manufacturing landscape by democratizing access to precision engineering. While challenges like funding and training persist, trends toward digitalization, sustainability, and localized production signal robust growth. Strategic investments in education, infrastructure, and policy frameworks will unlock their full potential, positioning these machines as cornerstones of industrial development in emerging economies.

This concise report balances technical insights with market context, suitable for business or academic use. Let me know if you need further refinements!

A Comprehensive Guide to Purchasing Small CNC Milling Machines in the U.S.

A Comprehensive Guide to Purchasing Small CNC Milling Machines in the U.S.

Application and Future Trends of Small CNC Milling Machines in Developing Countries: Focus on South America

Application and Future Trends of Small CNC Milling Machines in Developing Countries: Focus on South America

The Application of Small CNC Milling Machines in the Gold Jewelry Industry

The Application of Small CNC Milling Machines in the Gold Jewelry Industry

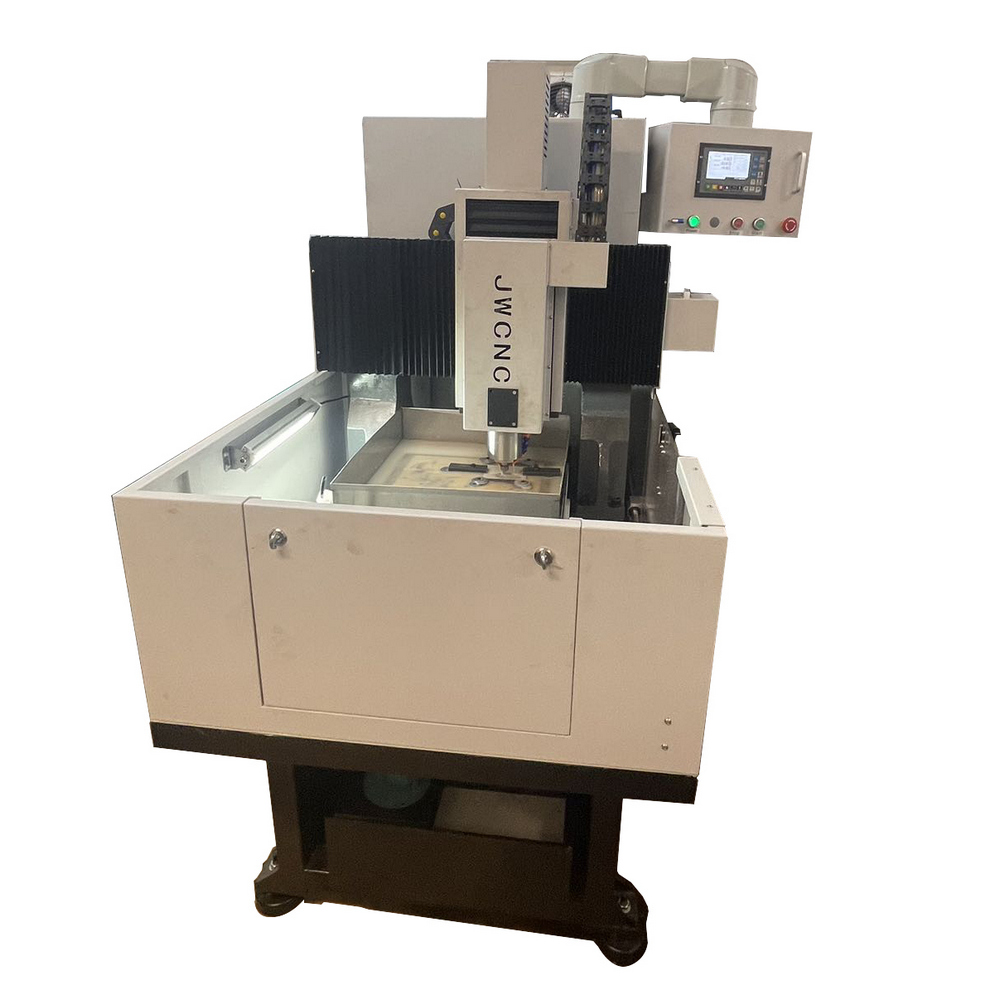

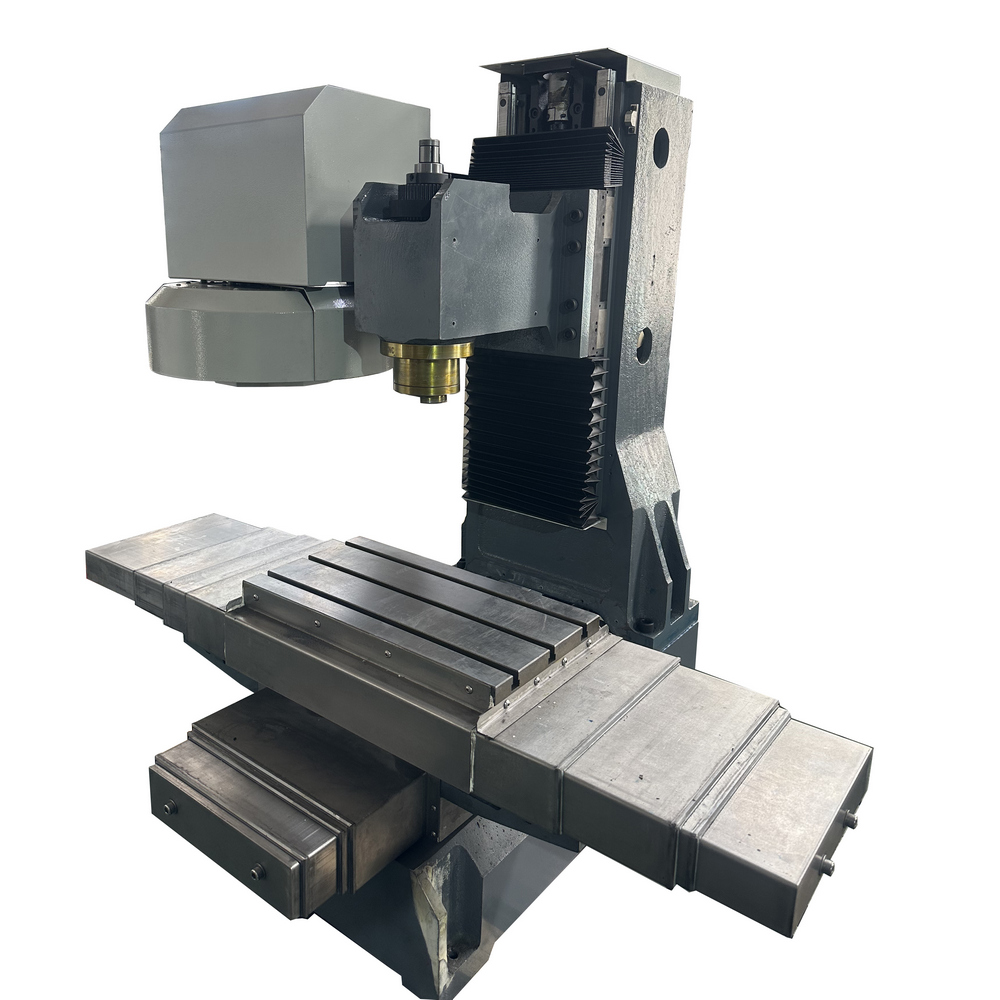

A high-quality CNC small machine starts with a robust frame that is sturdy, stable, and highly precise

A high-quality CNC small machine starts with a robust frame that is sturdy, stable, and highly precise

Please contact us with your request

We are ready to answer your questions.