The Growing Role of Small CNC Milling Machines in Automotive and Motorcycle Parts Manufacturing: A Focus on Emerging Markets

The global automotive and motorcycle parts industry is increasingly reliant on precision manufacturing technologies, with small CNC milling machines emerging as critical tools for cost-effective and flexible production. Models like the **VMC210**, **VMC420**, and **VMC425** vertical machining centers are gaining traction in emerging markets such as Mexico, South America, Africa, Southeast Asia, and Russia. These regions, characterized by growing industrialization and demand for localized manufacturing, are leveraging these compact yet powerful machines to enhance productivity and competitiveness.

1. Mexico: A Hub for Automotive Manufacturing

Mexico’s proximity to the U.S. automotive market has made it a hotspot for parts suppliers. Small CNC milling machines, particularly the **VMC420** and **VMC425**, are widely adopted for producing engine components, transmission parts, and custom motorcycle accessories. Their compact size and high-speed capabilities align with the needs of small-to-medium enterprises (SMEs) aiming to meet stringent quality standards while minimizing factory footprint. Additionally, Mexico’s focus on nearshoring has accelerated investments in agile manufacturing systems, where the **VMC210** excels in prototyping and low-volume, high-mix production.

2. South America: Balancing Cost and Complexity

In countries like Brazil and Argentina, economic fluctuations have pushed manufacturers to adopt affordable yet versatile solutions. The **VMC210** has become popular for machining aluminum motorcycle frames and brake components, offering a balance between precision and affordability. Meanwhile, the **VMC420** is favored for automotive gearbox parts, thanks to its rigid structure and ability to handle tougher materials like steel alloys. Challenges such as inconsistent power supply in remote areas have driven demand for energy-efficient models like the **VMC425**, which integrates smart power management systems.

3. Africa: Emerging Industrialization

Africa’s motorcycle market is booming, driven by urbanization and the need for affordable transportation. In Nigeria, Kenya, and South Africa, small CNC mills like the **VMC210** are critical for producing replacement parts such as sprockets, brackets, and engine casings. The **VMC425**, with its advanced cooling systems, proves advantageous in regions with high ambient temperatures. Governments’ push for local manufacturing to reduce import dependency has further boosted adoption, particularly for machines that require minimal operator training.

4. Southeast Asia: Rapid Expansion and Export Focus

Southeast Asia’s automotive sector, led by Thailand, Vietnam, and Indonesia, relies heavily on CNC technology for export-oriented production. The **VMC420** and **VMC425** dominate here, machining complex motorcycle suspension parts and aluminum die-cast automotive components. Their high spindle speeds (up to 12,000 RPM) and compatibility with automation systems align with the region’s emphasis on scalability. Additionally, the **VMC210** supports aftermarket parts manufacturing, catering to the region’s vast motorcycle repair network.

5. Russia: Localization Amid Global Pressures

Sanctions and supply chain disruptions have forced Russian automotive firms to prioritize localized production. Small CNC mills like the **VMC425** are now essential for producing sanctions-hit components, including fuel injection systems and transmission gears. The machine’s multi-axis capabilities enable manufacturers to reduce reliance on imported parts. Similarly, the **VMC420** is widely used in Ural and Siberia-based workshops for motorcycle customization, leveraging its durability in harsh climates.

Key Advantages of VMC210, VMC420, and VMC425

VMC210: Ideal for SMEs, offering low setup costs and flexibility for small-batch jobs.

VMC420: Balances power and precision for medium-sized components, widely used in gear and engine part production.

VMC425: Advanced features like IoT connectivity and energy efficiency make it a future-proof choice for high-volume markets.

Conclusion

From Mexico’s export-driven factories to Africa’s grassroots motorcycle workshops, small CNC milling machines are transforming automotive and motorcycle parts manufacturing. Models like the **VMC210**, **VMC420**, and **VMC425** are not just tools but strategic assets, enabling businesses in emerging markets to compete globally. As these regions continue to industrialize, the demand for adaptable, cost-effective CNC solutions will only grow—solidifying their role in the future of manufacturing.

A Comprehensive Guide to Purchasing Small CNC Milling Machines in the U.S.

A Comprehensive Guide to Purchasing Small CNC Milling Machines in the U.S.

The Growing Role of Small CNC Milling Machines in Automotive and Motorcycle Parts Manufacturing: A Focus on Emerging Markets

The Growing Role of Small CNC Milling Machines in Automotive and Motorcycle Parts Manufacturing: A Focus on Emerging Markets

The Application of Small CNC Milling Machines in the Gold Jewelry Industry

The Application of Small CNC Milling Machines in the Gold Jewelry Industry

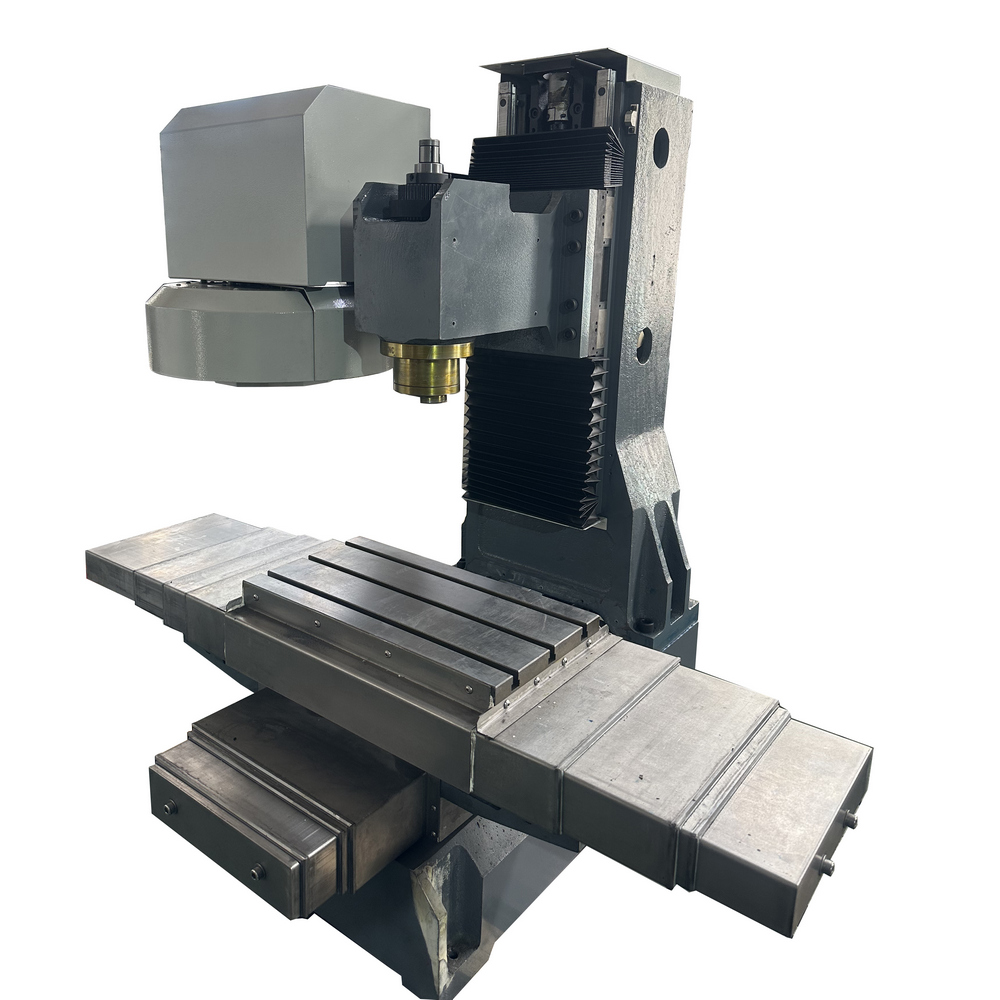

A high-quality CNC small machine starts with a robust frame that is sturdy, stable, and highly precise

A high-quality CNC small machine starts with a robust frame that is sturdy, stable, and highly precise

Please contact us with your request

We are ready to answer your questions.