A Comprehensive Guide to Purchasing Small CNC Milling Machines in the U.S.

Investing in a small CNC milling machine is a strategic decision for hobbyists, small businesses, and educational institutions aiming to enhance precision and efficiency in metalworking projects. This guide outlines key considerations to help you select the right machine for your needs, focusing on U.S.-available options and industry standards.

### **1. Define Your Requirements**

#### **Application and Materials**

Identify the primary use of the machine: prototyping, small-batch production, or educational purposes. Determine the materials you’ll work with (e.g., aluminum, steel, plastic) and the complexity of designs. For example, Haas Mini Mill 2 is ideal for aluminum and plastics, while Bantam Tools’ desktop mill excels in high-speed aluminum cutting .

#### **Budget**

Small CNC mills in the U.S. typically range from **$3,000 to $10,000**. Entry-level models like the Genmitsu 3018-ProVer V2 ($500–$1,000) suit hobbyists, while advanced machines like the Tormach PCNC 440 ($8,000–$12,000) offer industrial-grade performance .

#### **Space Constraints**

Ensure the machine fits your workspace. Compact models like the Haas Desktop Mill (20" x 16" x 14") or Pocket NC V2-50 (18" x 18" x 18") are designed for benchtop use .

### **2. Key Technical Specifications**

#### **Precision and Accuracy**

Look for machines with **ball screws** and **linear guides** for tight tolerances (e.g., ±0.01 mm). The Syil X7 and Sherline Model 5400 are known for their precision in small-scale machining .

#### **Spindle Power and Speed**

Spindle speed (RPM) and power (HP) determine material compatibility. For example:

- **10,000–15,000 RPM**: Suitable for aluminum and plastics (Haas Mini Mill 2).

- **24,000–28,000 RPM**: Ideal for high-speed machining of softer metals (Bantam Tools) .

#### **Work Envelope**

Match the **XYZ travel** to your part size. Common sizes include:

- **12" x 4" x 5.375"**: Sherline Model 5400.

- **20" x 16" x 14"**: Haas Mini Mill 2 .

#### **Control System**

Choose user-friendly software like **GRBL** (Genmitsu) or **PathPilot** (Tormach). Advanced systems like **Siemens 808D** (Syil X7) offer multi-axis capabilities .

### **3. Top U.S. Brands and Models**

#### **Haas Automation**

- **Haas Mini Mill 2**: A versatile machine with a 40-taper spindle and 15,000 RPM option, suitable for both hobbyists and manufacturers .

- **Haas Desktop Mill**: Budget-friendly for educational use, featuring a 15,000 RPM spindle and compact design .

#### **Tormach**

- **PCNC 440**: Equipped with a 10,000 RPM spindle and automatic tool changer, ideal for small shops .

#### **Bantam Tools**

- **Desktop CNC Milling Machine**: High-speed (28,000 RPM) and rigid, designed for aluminum cutting .

#### **Sherline Products**

- **Model 5400 CNC Mill**: Precision-focused with a 10,000 RPM spindle, popular among hobbyists .

#### **Grizzly Industrial**

- **G8689 Mini-Mill**: Affordable with a 3/4 HP motor, suitable for beginners .

### **4. Supplier and After-Sales Considerations**

#### **Local Suppliers**

Purchase from reputable U.S. suppliers like **Haas Automation**, **Tormach**, or **Little Machine Shop** for faster delivery and local support. Verify certifications like **ANSI B11.8-2021** for safety compliance .

#### **Warranty and Support**

Most brands offer **1-year warranties** covering parts and labor. Tormach and Haas provide additional technical support and training resources .

#### **Accessories and Spare Parts**

Ensure the supplier offers readily available accessories (e.g., ER collets, cutting tools) and spare parts. For example, Grizzly Industrial and Little Machine Shop stock a wide range of compatible components .

### **5. Purchasing Steps**

1. **Research**: Compare models using reviews (e.g., BestReviews.guide) and manufacturer specs.

2. **Request Demos**: Ask suppliers for virtual or in-person demonstrations to test performance.

3. **Check Compatibility**: Ensure the machine works with your CAD/CAM software (e.g., Fusion 360, VCarve).

4. **Negotiate Terms**: Inquire about bulk discounts, financing options, or bundled accessories.

5. **Inspect Upon Delivery**: Verify the machine’s condition and conduct a trial run.

### **6. Common Pitfalls to Avoid**

- **Underestimating Power Needs**: A 1/2 HP spindle may struggle with steel; opt for 1–2 HP for metalworking.

- **Ignoring Safety Features**: Ensure the machine meets ANSI B11.8-2021 standards, including emergency stop buttons and enclosure guards .

- **Overlooking Training**: Factor in costs for operator training, especially for complex systems like Siemens 808D.

### **7. Conclusion**

A small CNC milling machine is a versatile tool that can transform your workshop’s capabilities. Prioritize brands like **Haas**, **Tormach**, or **Bantam Tools** for reliability and performance. Always balance budget with technical requirements, and leverage U.S.-based suppliers for seamless support. By following this guide, you’ll make an informed decision that aligns with your machining goals.

*For further assistance, contact suppliers directly or visit industry forums like [CNC Zone](https://www.cnczone.com/) for user insights.*

*Note: Prices and availability are subject to change. Always verify details with suppliers before purchase.*

Application and Future Trends of Small CNC Milling Machines in Developing Countries: Focus on South America

Application and Future Trends of Small CNC Milling Machines in Developing Countries: Focus on South America

A Comprehensive Guide to Purchasing Small CNC Milling Machines in the U.S.

A Comprehensive Guide to Purchasing Small CNC Milling Machines in the U.S.

The Application of Small CNC Milling Machines in the Gold Jewelry Industry

The Application of Small CNC Milling Machines in the Gold Jewelry Industry

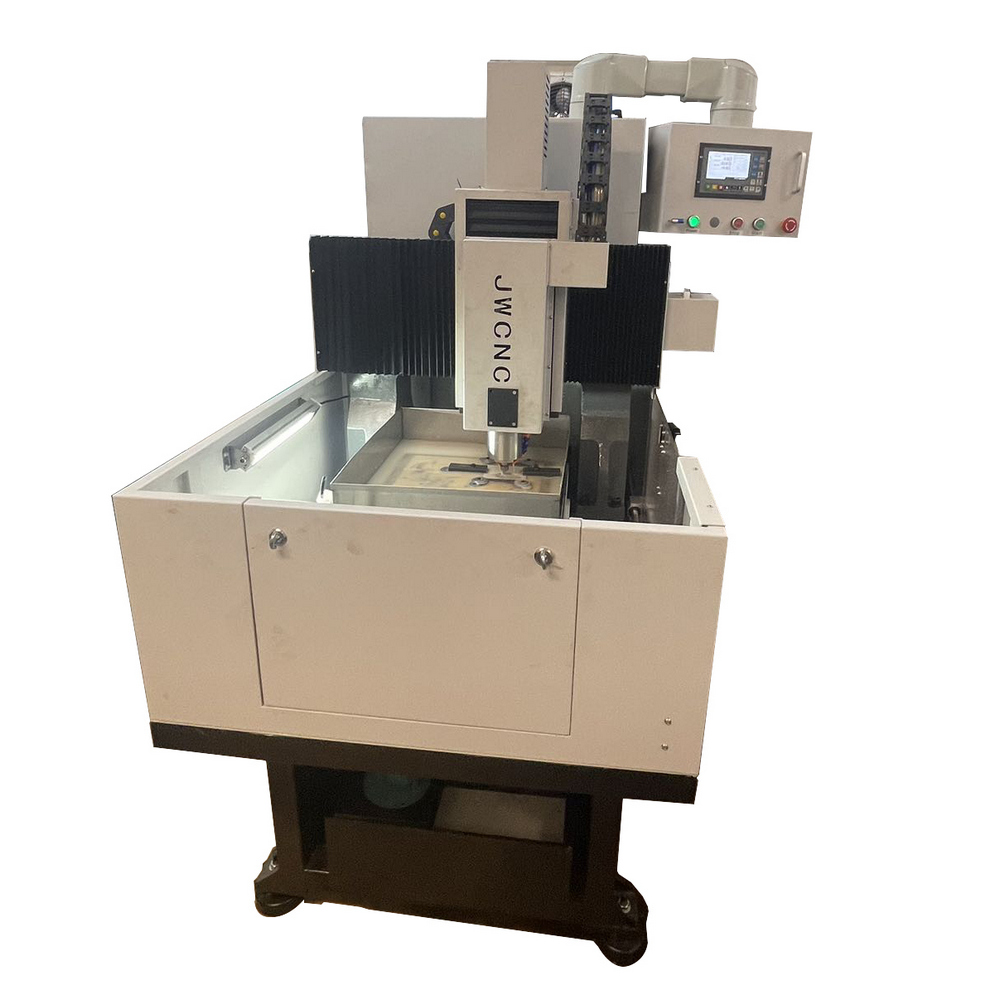

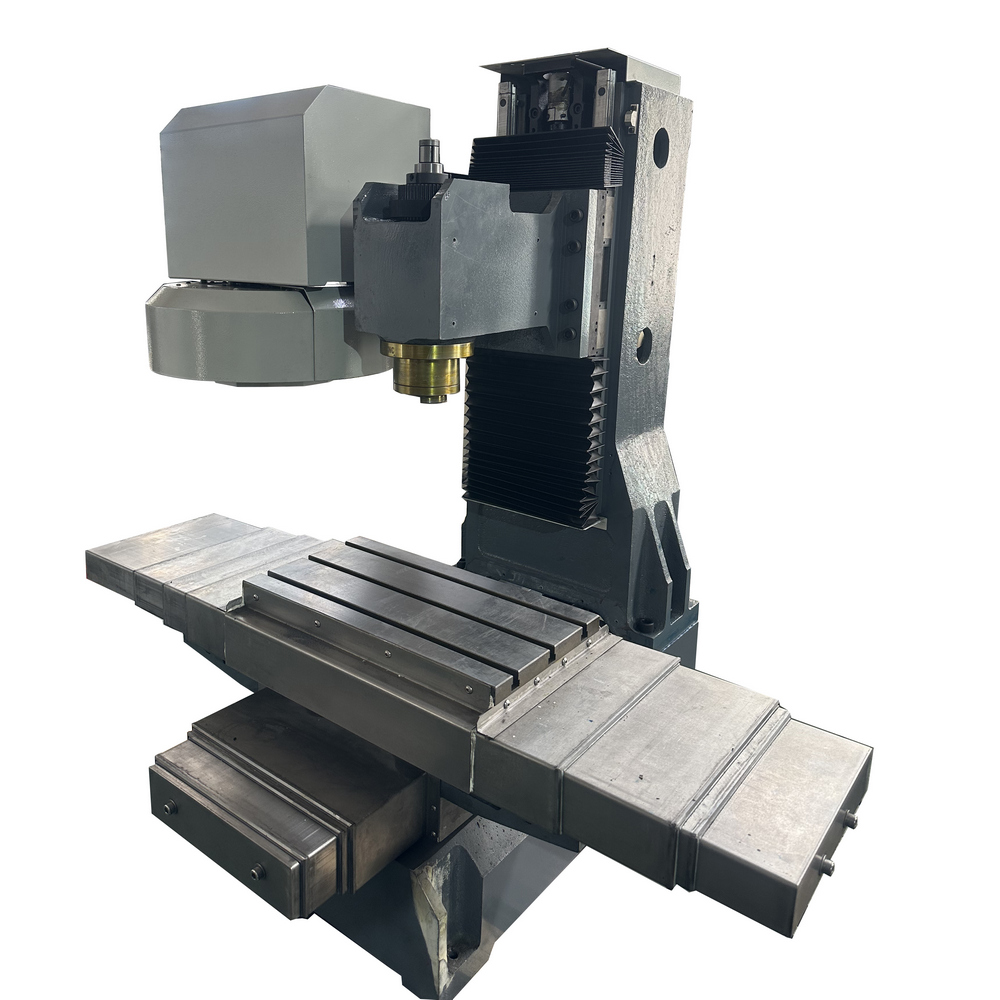

A high-quality CNC small machine starts with a robust frame that is sturdy, stable, and highly precise

A high-quality CNC small machine starts with a robust frame that is sturdy, stable, and highly precise

Please contact us with your request

We are ready to answer your questions.